For 50 years we have been developing innovative thermoplastic films with the aim of improving their performance, minimizing the environmental impact.

A story of a business born in the family, grown in our territory, exported all over the world.

WE ARE THE CHEMISTRY OF

CHANGE.

We believe in a sustainable future and we’ll do our best to achieve it through recycling, efficiency and awareness

WE ARE THE CHEMISTRY OF

SOLUTIONS.

We adapt on our clients’ needs to always find the correct solution

WE ARE THE CHEMISTRY OF

RELATIONS.

We take care of our clients in every stage of the process

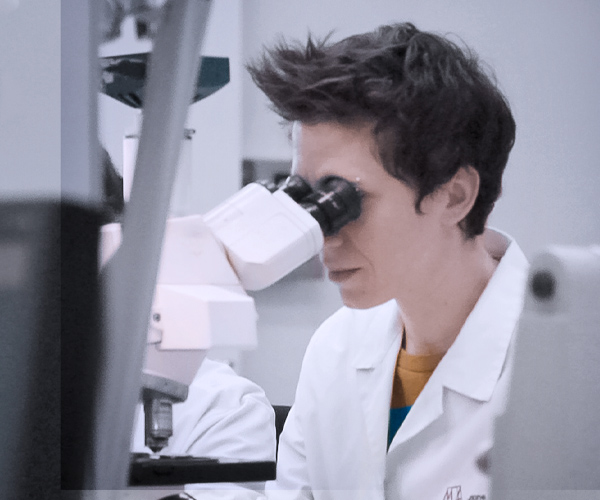

WE ARE THE CHEMISTRY OF

IDEAS.

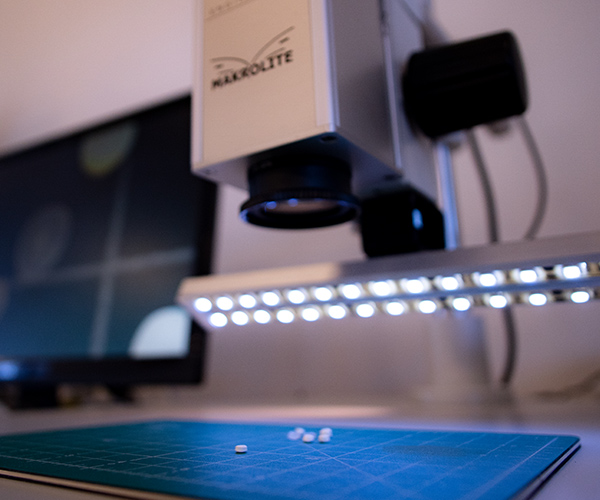

We have always invested in research and development with commitment and dedication